PROJECT BACKGROUND

COOPERATION STUDENT PROJECT WITH BRAUN GROOMING

In the course of a cooperation project with Braun Grooming, a new trimmer was to be developed for Braun. The research was done in teams, the development of concepts and designs in individual work.

THE SOLUTION

SLIM TRIMMER WITH REVERSIBLE BLADE

My obvious approach was to create a product with a slim design that meets the requirement of enabling and optimising both coarse but especially precise trimming.

PRODUCT SEGMENT

IN BETWEEN PRECISE AND CLASSICAL TRIMMER

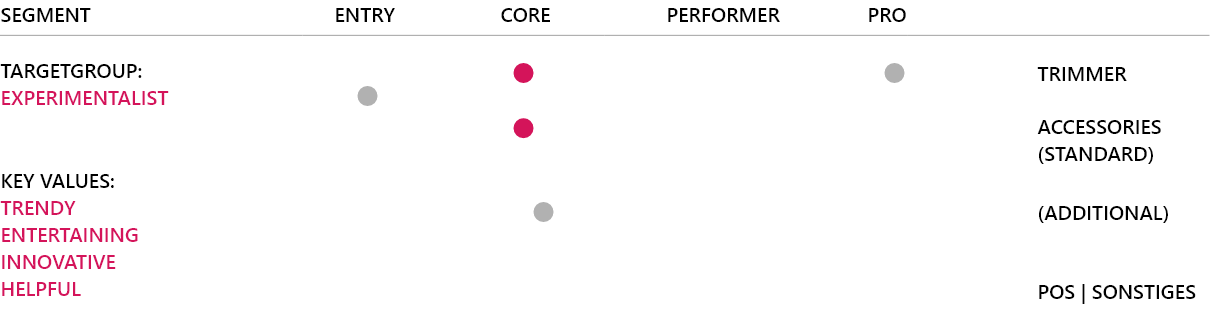

At that time, there were only very few products from Braun for the still sparsely populated area of trimmers with reversible blades that enable both wide-area and precise trimming. I therefore decided to design a reversible blade trimmer for this segment, which is intended for users who are looking for this functionality, but who want to do without the numerous accessories found in classic multitools.

SECONDARY RESEARCH

Assembling the rotating mechanism

I disassembled trimmers with similar functionality to get a feel for the product dimension I would be working with. We received the technical package from Braun. I added the rotation mechanism and started to work out proportion and shape studies.

Mood

MINIMALISTIC HERITAGE MEETS MODERN DETAILS

The basic idea was to create a very smooth minimalist design with few surfaces, but which would impress with interesting housing divisions and chamfers.

Design DEVELOPMENT

SEARCHing THE PERFECT form FIT

I used a variety of foam models to try to find a shape that was as slim as possible, while maintaining the minimum product dimension. In the process, I played with various profiles and curves. When I found an ergonomic shape, I tested a variety of different housing partitions, materials and interface variants first in sketch form and then in Photoshop. I converted my favourite design into a 3D model and created photo-realistic renderings.

REVERSIBLE BLADE